The industrial centrifugal fans with simple suction, are the most used in industrial suction systems, and for a correct installation must be completed with a series of accessories to connect to the pipes and ground or wall support.

Industrial centrifugal fans with simple aspiration are the most used in the aspiration systems for the reclamation of welding fumes, grinding, sanding or other pollutants produced by surface treatments in industry and crafts.

The reasons that make these centrifugal fans, especially simple suction, particularly suitable for the suction systems already listed above, are:

which guarantee high performance and, above all, the possibility of sucking in unclean air, without having any problems even in continuous operation; this is essential where it is necessary to suction dusty air, in the presence of sawdust, various chips, granular materials (excluding filamentary materials).

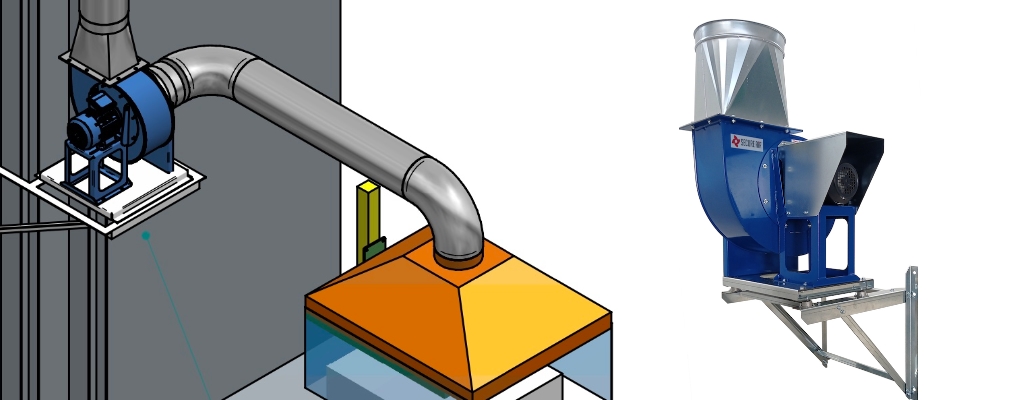

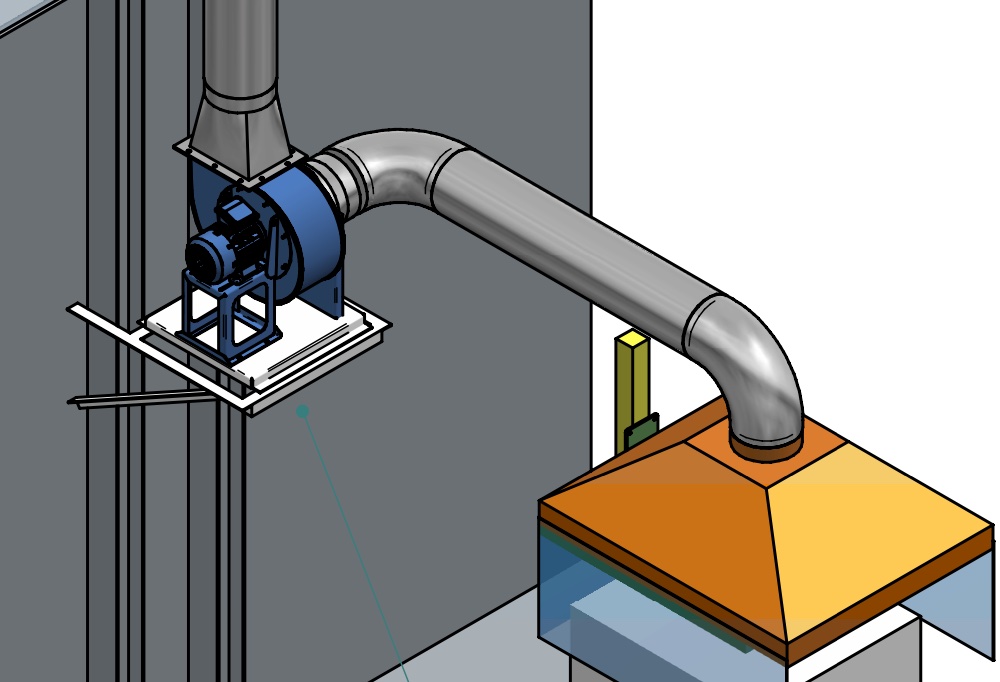

| The centrifugal fan is often supplied by the manufacturer without accessories, but in order to fit these fans along a pipe of a suction system, such as the one shown on the right, simple suction versions need many components to complete, essential for a correct installation. |  |

| Although often underestimated by installers, these fittings are fundamental because they have the task of connecting the fan correctly and effectively to the pipes of the system, avoiding turbulence (in case they are too narrow section). They must be made to measure perfectly compatible with the suction and discharge flanges, so as to avoid unwanted air leakage. It is highly recommended to add to the circular fittings the anti-vibration joints that have the fundamental function of isolating the pipes from the possible vibrations of the fan. |  |

| The centrifugal fan is usually installed on the ground or on the wall, depending on the path of the pipes in the suction system. In both cases, weatherproof and heavy-duty components are required for proper installation. Speaking of bad weather, it is essential in case of installation outside to provide the protective carter of the engine that significantly extends the operating life, protecting it from sunlight and rain. |  |

The three-phase industrial inverter, in applications with centrifugal fans, guarantees the best energy efficiency in creating systems with variable flow. In these cases, the power absorbed is proportional to the cube of the speed, with significant energy savings:

|

|

Our technical department is available for further clarification, simply fill in the form at the bottom of the page to be contacted by a specialist.

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications