The suction benches for independent welding and grinding are those complete with extractor and filters that allow the operator to work safely and protect the environment but which bench to choose for their business?

The suction benches for welding and grinding complete with extractor and filters are modern equipment that have become very important in a mechanical workshop or in general in professional contexts because they allow the operator to work safely and to protect the working environment from pollutants that are typically produced during metal processing, the fumes and micro-powders that “hover” in the air of the laboratories and that are then those breathed and absorbed at the alveolar level with serious health consequences.

In the video below you can appreciate the effectiveness of a suction bench, in the box on the right with the suction bench off while in the one on the left the suction plane is on and as you see no smoke rises towards the respiratory tract of the operator working in safety and respiratory protection.

Without doubt, therefore, the purchase of a suction bench is an important step in the growth of every company, also in consideration of the fact that this machinery fully meets the requirements of D.lgs. n 81 or the need to aspirate at the source and in a localized way the fumes and dust of any species in order to collect them near the place where they are produced.

If you are looking around for your first bench or are planning to switch to a suction bench, keep reading this article.

We will try to provide you with a series of elements on which to focus your attention to choose the model that best meets your needs within the budget you have available.

First thing to consider carefully, do we just want to grind, smudge or sand metal parts or do we also have to weld? This is a very important question to ask because the grinding powders deposited on the filters do not agree at all with the sparks of welding and if the bench is not equipped with special metal protections it is not advisable to use it for both processes.

For example, if we only have to do welding, a progressive clogging filtration is sufficient, as for example is the case for the SBV series, while if we must mostly grind and sand, it is better to choose self-cleaning filters such as the SBC series.

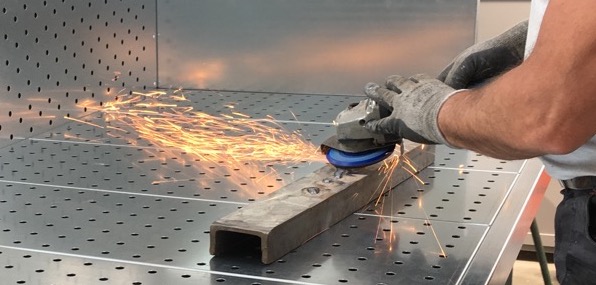

In the video below you can see a grinding operation on a suction bench

In the case of a grinding suction bench such as the one in the video, the front wall is completed with an anti rebound metal mesh to prevent sparks from turning back towards the operator.

It is important to remember that the suction bench bases its working efficiency precisely on the plane that being slatted or perforated sucks the fumes and dust down, so it is of fundamental importance to choose a size that allows you to comfortably place the pieces to be processed.

In the case of long and narrow details remember that the side bulkheads of the benches are normally removable so we can support them and then intervene with the processing only in the stretch that rests on the suction plane.

Normally the depth of the worktop is fixed and equal to about 71 cm while the width of the worktop can vary from a minimum of 1mt up to 3 meters with the possibility of inserting central dividers to operate two people on the same bench.

The load capacity of a slatted suction is about 130kg/sqm evenly distributed on its surface, this usually meets most of the work needs but for example in the case of suction benches used for the processing of moulds or cast iron parts such as valves, reinforcements are needed to prevent the slats or perforated panels from bending too much.

These are the three main points to take into account for the correct selection of an independent suction bench, that is complete with filters and extractor on board, without the need to connect to an external suction system, a very useful and flexible solution.

Fill in the form below to request a quote by email, agree on special conditions, or technical clarifications